Total Customer Satisfaction

Data-Matique services some of the most complex and advanced industries in the world making quality control tremendously important. We continuously monitor accuracy of measurements, machining and overall performance.

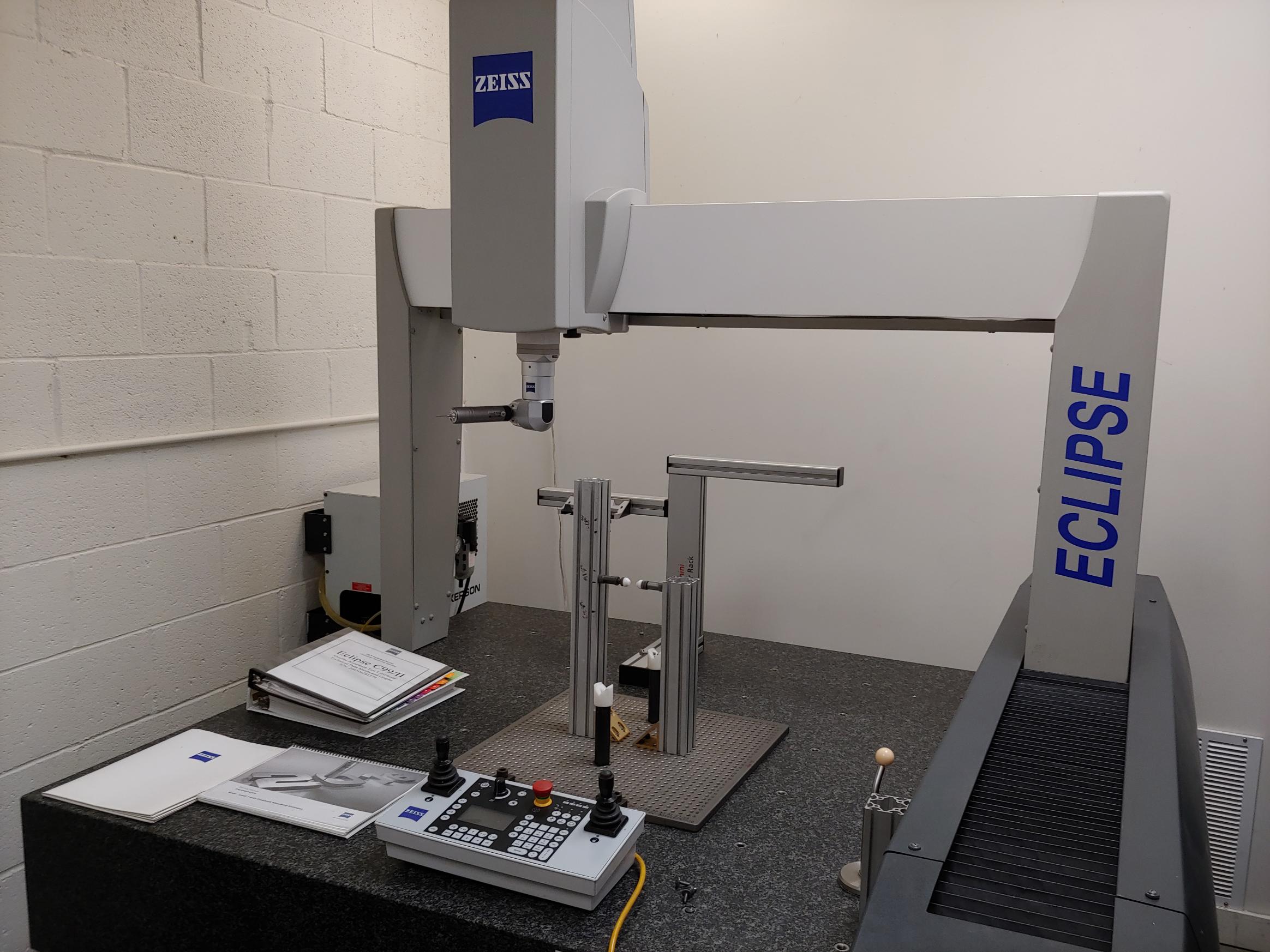

We are proud to hold the ISO 9001:2015 and AS9100D certification, which means that we adhere to a very strict subset of principles and a family of standards for Quality Management Systems. Our staff is experienced in all areas of quality control and we have highly trained individuals in Just-In-time Inventory Management, mathematical assimilation, measurement reading, print tolerances, CNC programming and on-site safety. Additionally we utilize CMM on premise for precision inspection and use system exams and processes for validation and controls and regulatory approvals.

Inspection Equipment

Data-Matique travels the world to find the very best in state of the art inspection technology. We are committed to meeting and/or exceeding quality control standards in machining and fabrication. Some of our inspection equipment includes:

Benefits of Quality Assurance

Regardless of product, service, or industry, quality assurance presents a host of benefits to all companies, including by helping them:

- Meet or exceed their customers’ demands and expectations

- Ensure products comply with all applicable statutory, and industry standards

- Establish and maintain high quality product and service standards

- Build brand reputation and customer trust

- Reduce overall production costs and material waste (for product suppliers)

- Be proactive, not reactive, to product or service issues

-

(1) Carl Zeiss Eclipse CMM 40”X40”X24”,Calypso Software Angle Plates

-

(1)14" Rank Vertical (Shadow Graph) Comparator/With Standard Equipment

-

(3) 24" Mitutoyo Microheight Gauge

-

(3) 24" Brown & Sharp Tesa Height Gauge

-

(1) 24" Vernier Caliper

-

(1) Inside Micrometer To 12"

-

(1) Outside Micrometer To 12"

-

(2) Set Of Jo-Blocks

-

(1) Sheffeld Discovery II Cmm

-

(1) Hardness Tester

-

Angle Plates

-

Plug And Ring Gauges From .011-1.000

-

Other Small Tools For Various Inspections

FAQ's

Inventory management

FOR ALMOST FIVE DECADES, DATA-MATIQUE HAS

USED A REPUTABLE AND EFFECTIVE INVENTORY MANAGEMENT SYSTEM, SO THAT EACH

CUSTOMER’S PROJECT AND GOALS CAN BE LOCATED THROUGHOUT THE ENTIRE PRODUCTION

PROCESS TO ENSURE ACCURACY AND ON-TIME COMPLETION.